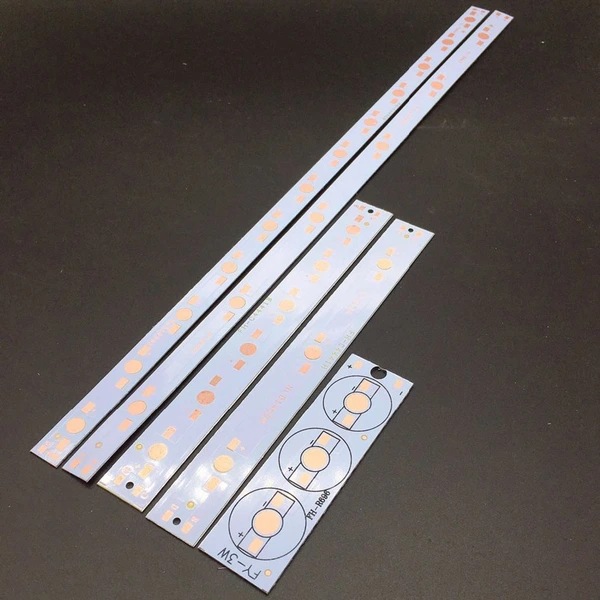

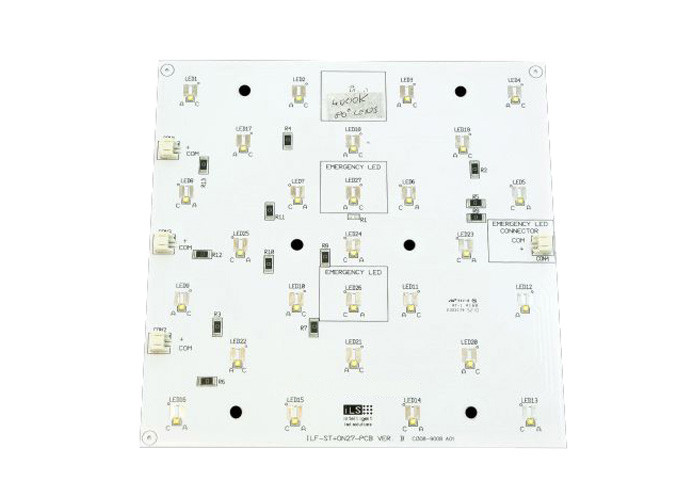

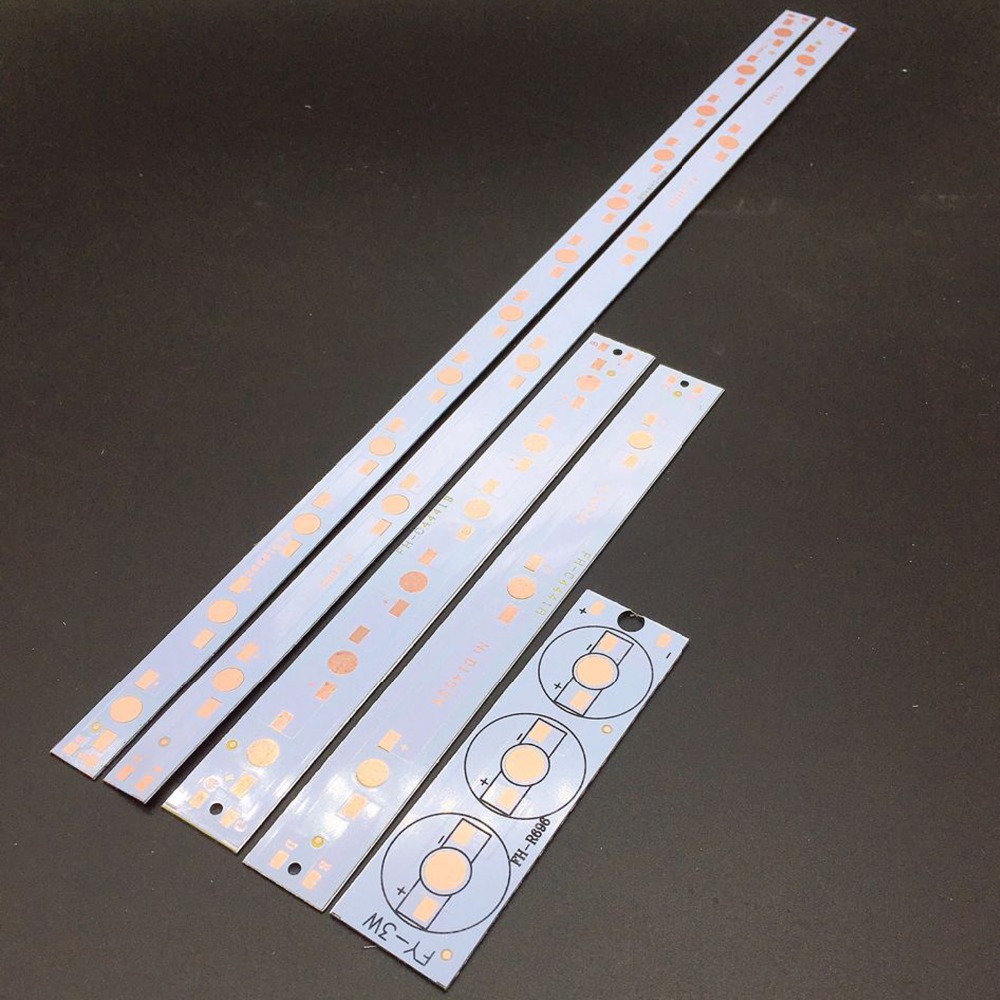

Among all Metal core PCBs,Aluminum PCBs is the most common type - the base material consists of aluminum core with standard FR4. It features a thermal clad layer that dissipates heat in a highly efficient manner, while cooling components and increasing the overall performance of the products. Currently, Aluminum Backed PCBs is regarded as the solution to high power and tight tolerance applications.

Advantages of Aluminum PCB

1.Environmentally Friendly: Aluminum is non-toxic and recyclable. Manufacturing with aluminum is also conducive to conserving energy due to its ease of assembly. For printed circuit board suppliers, using this metal helps maintain the health of our planet.

2.Heat dissipation: High temperatures can cause severe damage to electronics, so it is wise to use a material that can help dissipate heat. Aluminum can actually transfer heat away from vital components, thus minimizing the harmful effect it could have on the circuit board.

3.Higher durability: Aluminum provides strength and durability to a product that ceramic or fiberglass bases cannot. Aluminum is a sturdy base material that can reduce accidental breakage during manufacturing, handling, and everyday use.

4.Lightweight: For its incredible durability, aluminum is a surprisingly lightweight metal. Aluminum adds strength and resilience without adding on any additional weight.

Metal core PCBs have a unique set of advantages compared to other base materials:

Less expensive. Aluminum is indigenous to a variety of climates, so it’s easy to mine and refine. That makes it significantly less expensive to mine and refine than other metals. By extension, the manufacturing costs associated with products using aluminum PCBs are also less expensive. Aluminum PCBs are also a less expensive alternative to heat sinks.

Friendly to the environment. Aluminum is a non-toxic, recyclable metal. From the manufacturer through to the end consumer, using aluminum in PBCs contributes to a healthy planet.

Better heat transfer. High temperatures are the cause of heavy damage to electronics. Aluminum conducts and transfers heat away from critical parts to minimize damage to the printed circuit board.

Very durable. Aluminum is stronger and more durable than base materials like ceramic and fiberglass. It is very sturdy, and reduces accidental breakages that can occur throughout the manufacturing process, and during handling and everyday use.

Lightweight: Considering its durability, aluminum is very lightweight. It adds strength and resilience to PCBs without adding additional weight.

We like our clients to be as informed as they can about the different types of products we offer at MCL. Even though power converters and lighting projects are the largest users of metal-based PCB’S, there are many different uses. LED PCB manufacturers make up the majority of metal-based circuit boards, , it may benefit from the advantages of aluminum-core PCB material. Every Aluminum core PCB supplier should help their customers assess their needs for thermal control and insulation. Aluminum Core PCB’s are typically used with White or Black solder mask and MCL has a specific White mask for LED applications.